Tanker Production Line

-

Price Range: $1,000.00 - $30,000.00 / Set -

MOQ: 1 Set/Sets (Min. Order) -

Model Number: -

Lead Time:Quantity(Sets) 1 - 100 101 - 200 >200 Estimated Time(Days) 30 40 Negotiable -

Core strengths:1. 20 years manufacturer & trading company with powerful strength.

All Core Strengths

2. One stop solution provider.

3. OEM&ODM services are available.

4. Flexible payment terms:T/T,Cash,Western Union,L/C,etc.

- Tel +86 13838293687

- Email gm@yuedatech.com

Product description of tanker production line:

With years of development, our company has designed and manufactured various complete welding production line equipment for special vehicles, including the mixer truck production line, tank truck production line, box truck production line, etc. At present, they are widely used by special automobile enterprises such as Hubei Jiangshan Heavy Industries Co., Ltd., China International Marine Containers Co., Ltd. (CIMC), HuBei Chengli Special Automobile Co., Ltd. and Huanghai Automobile Co., Ltd. Our company can produce various products and customized production lines according to the specific requirements of users.

Tank body gantry welding machine:

Irregular-shaped tank gantry welding machine:

Head assembly machine:

The head assembly machine, mainly used for assembly welding of tank head, consists of the head clamp, base, turnover mechanism and translation mechanism, adjustable turning rolls and electric control box, keeping the workpiece in the optimal welding or assembly place through turnover and translation. The machine can form a special welding machine in combined with the gantry welding manipulator.

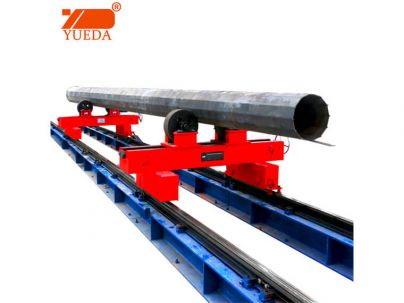

Chain turnover machine:

The chain turnover machine is used to turn the workpiece to be welded to the required position, preventing the workpiece from twisting and deforming during the process. It has the advantages of simple structure, convenient operation, easy maintenance, high bearing capacity, less pollution, etc., and is widely used in H-shaped steel, semi-trailer, cement bulk vehicle and other production fields.

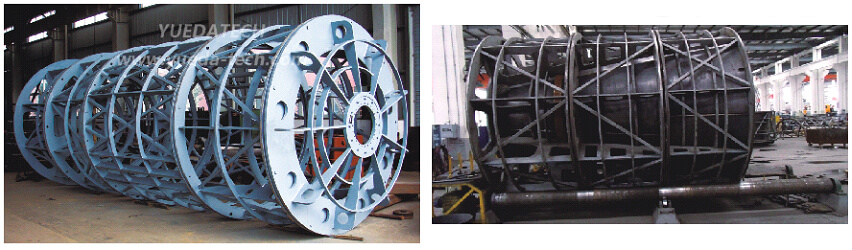

Cage tooling:

The cage tooling is used for assembly welding of mixing barrel, and is made of steel plate and profile through butt welding, with high strength. Before assembly, it is convenient for workers to weld the spiral lamina inside the shell course and also play the role of external tightening, to avoid welding deformation. The manufacturing precision of flange part meets the precision requirements of the assembly.

Hydraulic lifting vehicle:

The hydraulic lifting vehicle has low initial height, and high table strength, and is convenient for maintenance. Not only can it be used as a common flat transportation vehicle, but also has the function of hydraulic lifting, making it an ideal handling equipment for concrete mixer truck production line, concrete bulk vehicle production line and other barrel production lines.

| Tank production line main parameters | |

| Item | Parameter |

| Machine type | Tanker production line |

| Tank type | Fuel tank,oil tank, water tank, food tank, LPG tank, etc |

| Tank capacity | 5KL-50KL or customized |

| Tank diameter | 1500-3000mm |

| Tank length | 3000-9500mm |

| Welding speed | 100-1000mm/min or customized |

| Welding mode | MAG, MIG or SAW |

| Power supply | 3 phase 380v/50hz or customized |

Welcome your inquiry, welcome to visit us. One stop solution is ready for you!